Description

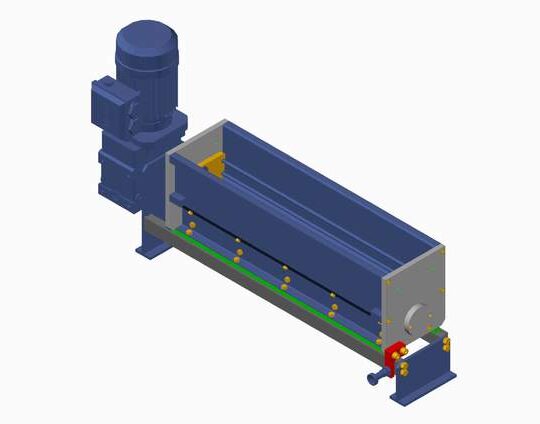

The cooling tunnel is designed for cooling and conveying confectionery products.

Techn. Data:

- Total length = Cooling length + ca. 2000m for inlet and outlet

- Cooling length: by arrangement – standard lengths 10m – 15m – 20m

- Belt width: 420 – 620 - 820mm – 1050 – 1300

Types of cooling:

Air cooling from above (convection cooling)

Air cooling from above (convection cooling) & bottom cooling

technical features:

- Convection cooling: air cooler – 1 pcs., Freon cooling unit – 1 pcs.

- Automatic belt alignment via pneumatic motor, mounted at the beginning and the end of the conveyor belt

- Automatic belt tightening via pneumatic motor

- Vulcanized rubber drive drum with variable frequency drive,

- Lengthwise adjustable knife edge

- Hoods are opened on both sides, equipped with gas springs for raising the hood

- High-performance polystyrene thermal insulation

- Scraper for belt cleaning with stainless steel chute for bulk goods

- Emergency stop buttons on both sides

- Condensate tray under the evaporator and pipe connections to get the condensate water away

- Stainless steel design

- Pneumatic control system is built in a separate cabinet above the table.

- 0.75kw geared motor by Motovario

- Frequency converter by Mitsubishi

- Temperature of cooling area: +6...+15°С

- Belt speed: up to 6 m/min

We offer this machine as NEW machine, with 6 months warranty